Tubular Centrifuge Machine

Working Principle

The centrifuge consists of machine body, driving part, bowl, liquid collecting pan and liquid-in bearing seat etc.

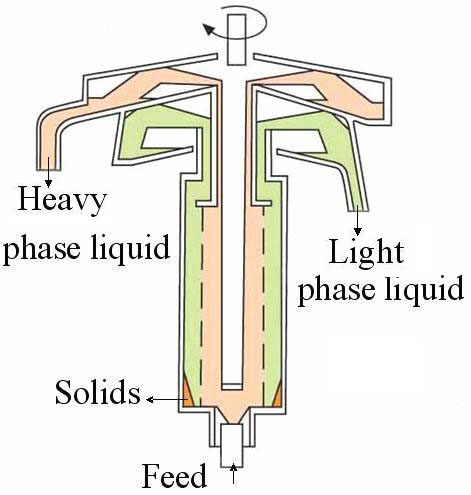

The material is sprayed onto the bowl from the inlet on the bottom and strong centrifuge force is formed when the bowl rotates with the material and that makes the material flow upper along the wall of the bowl and then separated because of the different gravity by the centrifuge force.

Heavy liquid (water) forms outer ring and light liquid (oil) forms inner ring. They flow to the top of the bowl and discharge from their respective outlet. And the little solid is settled on the wall of the bowl and discharged manually after the machine stops.

The motor connect with the big pulley and delivery the power to the spindle through the belt, tensioner and small pulley and rotate with the bowl in high-speed as the clockwise.

This characteristic results from a design that allows continuous feeding of a liquid-liquid-solid mixture (oil-water-impurity, blood cell & plasma, other immiscible two liquids with different density etc), while simultaneously expelling the two liquids component. The solids is retained in the bowl.

Two liquids are obtained from bi-level upper ports while the machine is running. Solids are taken from the tubular bowl after the machine is stopped.

Features & Benefit

1.Rapid separations

2.Consistent performance

3.Range of models: facilitate scale-up

4.Simple to set up, use and clean-for minimal down-time between separations

5.No replacement membranes, or costly disposables

6.Small footprint - saves space

7.Meet GMP requirements

8.Bowl is manufactured in five stages (rough turning/grinding, a solid solution treatment, pre-finishing turning, refinement, smooth turning/grinding) and is not subject to deformation

9.High speed bearing from Sweden SKF

10. Inlet and outlet openings of using quick-connection made of SUS304

Technical specification

Model | Bowl | Power | Dimension | Weight | |||||

Inner Dia(mm) | Height(mm) | Sedimentation Volume (L) | Max Speed (r/min) | Inlet Nozzle Dia(mm) | Water Through Capacity (L/h) | ||||

GQ/GF45 | 45 | 240 | 0.4 | 10000-28000 | 2/2.5/3 | 100 | 0.4 | 500*420*760 | 90kg |

GQ/GF75 | 75 | 450 | 2.2 | 20000 | 3/5 | 100-600 | 1.5 | 760*450*1120 | 300kg |

GQ/GF105 | 105 | 730 | 6 | 16300-19000 | 6/8/10 | 1200 | 2.2/3 | 840*500*1600 | 550kg |

GQ/GF125 | 125 | 730 | 8 | 15000 | 6/8/10 | 1500 | 3/4 | 900*550*1600 | 630kg |

GQ150 | 142 | 730 | 10 | 14000 | 6/8/10 | 2500 | 3/4 | 1020*600*1600 | 660kg |

Typical Application

It is mainly used for liquid-liquid-solid or liquid-liquid separation. For example:

1) Separation of blood(plasma and hemoglobin separation)

2) Vegetable Oil separation( degum, de-soap, water washing etc)

3) Animal oil separation ( fish oil, shrimp oil etc)

4) Industrial oil separation (HFO, WVO, bio-diesel, lubricating oil, distillate oil, transformer oil, hydraulic oil etc)

5) Oil extraction(Rose essence oil, orange oil, lemongrass essential oil, argar wood oil etc)

6) Waste water handling

7) Milk skimming, coconut oil and water separation

8) sea buckthron oil, evening primrose oil separation